Step-by-Step Guide to Making a Wooden Kitchen Bar Stool

by Guest Post on May 15, 2012

It's handy to have a couple of wooden bar stools in your kitchen, for sitting on whilst preparing food, reading a magazine while enjoying a cup of coffee, or for relaxing on whilst entertaining guests. The backless bar stool here has a simple and versatile design and can be finished in whatever color you choose to match your kitchen's décor.

What You Will Need

Materials:

- Wood: 90 x 19mm, 1 x 4.2m length

- 70 x 19mm, 1 x 1.8m length

- 40 x 19mm, 1 x 1.8m length

- Wood Glue

- Screws

- Nails

Tools:

- Sliding Bevel

- Protractor

- Saw

- Drill

- Hammer

- Tape Measure

- Pencil

- Plane

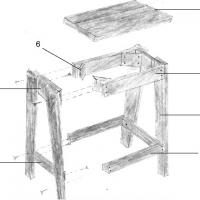

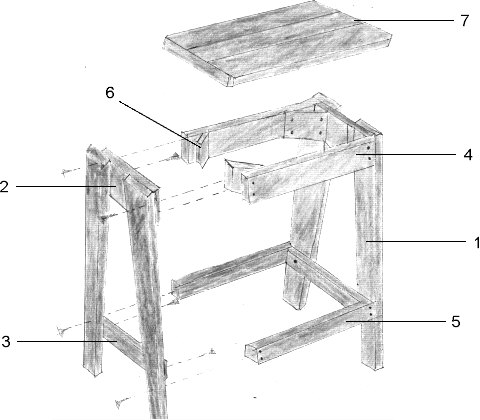

The wood will be cut to make the following parts, as shown on the diagram:

90 x 19mm

Legs (1) = 4 x 650mm lengths

Seat Slats (7) = 3 x 450mm lengths

70 x 19mm

Top Spreaders (2) = 2 x 230mm lengths

Top Rails (4) = 2 x 360mm lengths

Corner Blocks (6) = 4 x 100mm lengths

40 x 19mm

Bottom Spreaders (3) = 2 x 315mm lengths

Bottom Rails (5) = 2 x 360mm lengths

Instructions making your Bar Stool

Step 1 Cut the legs, giving each one a 5 degree splay. To do this, use the protractor to set your sliding bevel to 85 degrees. Use a pencil to mark the angle on your length of 90 x 19mm timber and cut along the line with a saw. Measure 630mm, mark the angle again and cut. Do this another 3 times until you have your 4 stool legs (1).

Step 2 On each leg, measure 45mm across the bottom and 400mm up the inside edge. Use your pencil to mark these points and then join them up. Cut along the pencil line to taper the legs.

Step 3 Use a plane to smooth off the cut edges. Remember to always work in the direction of the grain and plane downwards, taking thin shavings.

Step 4 Cut the top and bottom spreaders (2 and 3). The bottom side rails need to follow the splay of the legs, so each bottom spreader needs to have a 5-degree angle cut at each end. Lay one pair of legs on your work surface. Put pencil marks 19mm in from the top outside edge of each leg, and 19mm in from the outer edge, 150mm up from the bottom. Use high strength wood glue to glue and then screw the top and bottom spreaders in place, making sure you leave space for the rails.

Step 5 Cut the top and bottom rails (4 and 5). Glue and nail them to the spaces left on the legs in the previous step. Secure with screws from the legs into the end of each rail. Stand the stool upright to check its level and square, and make any necessary adjustments if you need to.

Step 6 Make the 4 corner blocks (6), cutting a 45 degree miter cut at each end. Screw them into the corners of the top spreaders and rails.

Step 7 Cut the 3 slats (7) to make the seat. Remove the sharp outside corners by cutting a small 45 degree triangle off each one. Glue and nail the slats to the stool, making sure you put the middle slat in position first.

Step 8 Use glued in dowelling to plug the counter bored screw holes. Cut the dowelling so it's flush with the wood.

Step 9 Sand all surfaces to get a smooth finish and then apply a coat of a hardwearing polyurethane coating to give your stool a protective finish.

About The Author

Dan O'Sullivan is a freelance writer with an interest in woodworking projects. He is a contributor to www.GetBarStools.com, where you can find a selection of discount bar stools as well as helpful advice on choosing kitchen bar stools for your home.

Popular Articles

Three Places to Spend Money on the Exterior of Your Home

When you have the exterior of your home remodeled, you are investing, time, energy and convenience into the project and you want to make sure that...

104891 Views

Homemade Headboards-Make an Upholstered or Wooden Headboard

Homemade headboards can add a lot of personality to any bedroom. They can be coordinated with existing furniture and room decor or they can be the...

80127 Views

When to Use a Brush, Roller or Sponge Brush

Brushes are a good choice for painting trim and woodwork. They are also useful for cutting in the edges around the top and bottom edges and corners...

72796 Views

Creating a Cottage Kitchen with Bead Board

Kitchen decor can range from modern and bold to elegant and elaborate by using strategic kitchen pieces. One of the most popular decorating trends...

58558 Views

Gas Fireplace Diagnostics and Troubleshooting

Follow these steps for diagnosing and troubleshooting Gas Fireplaces repairs. For the average DIYer, this may seem intimidating, depending on the...

35595 Views

Latest Articles

How Much Does it Cost to Take a Bath?

Plumbers know that a bath may seem like a relaxing luxury, but the real cost extends far beyond your water bill. The average soak uses 35 to 50...

on Apr 8, 2025

10 Concrete Patio Ideas on a Budget

A concrete patio can be a game-changer for your outdoor space. It is durable, versatile, and can be customized to fit your style. But what if you...

on Mar 25, 2025

Tips for Creating a Stunning Personalized Photo on Canvas

Order the unique beauty of a personalized photo on canvas and bring your memories to life. With a customized photo on canvas, you can transform...

on Mar 7, 2025

Best Areas to Buy Property in Singapore for Long-Term Growth

Singapore's real estate market remains one of the most stable and lucrative in the world. With limited land supply, strong governmental...

on Feb 18, 2025

Troubleshooting Excess Water in Your HVAC Secondary Condensate Drain Pan

When maintaining your air conditioning system, it is easy to overlook the condensate drain pan - until excess water starts pooling in places where...

on Jan 12, 2025

Featured Articles

What Type of Licensed Contractor Should You Hire?

on Feb 28, 2017

Hire Contractors / Estimates

Looking for a specialty project? There are many types of contractors available for your home improvement needs. Finding the right type of...

Sponsored Articles

Best Areas to Buy Property in Singapore for Long-Term Growth

on Feb 18, 2025

Real Estate / Finance

Singapore's real estate market remains one of the most stable and lucrative in the world. With limited land supply, strong governmental...

Actions

Top Categories

- Garden / Landscaping / Patio — 264

- Kitchen / Bathrooms — 240

- Real Estate / Finance — 203

- Appliance / Repair — 186

- Interior Design / Decor — 184

- HVAC / Air Conditioning — 148

- Cleaning / Maintenance — 144

- Improvements / Remodeling — 131

- Plumbing / Basements — 118

- Floors / Tile / Hardwood — 116

- Doors / Garages — 113

- Safety / Security — 113

Articles Archive

More DIY Articles

Are Smart Blinds Worth the Cost?

Two essential elements of a home are natural lighting and comfort. A home that is well lit and comfortable is the dream of every homeowner no...

How to Prepare Your House for Winter

Winter can cause damage to your house if you aren’t properly prepared. Preparing yourself for winter is simple. All most people need are gloves,...

How to Buy the Best Vacuum Cleaner? A Few DIY Steps to Follow

How should you choose the best vacuum cleaner? With literally hundreds of brands to choose from, finding the best vacuum can be difficult. Price...

Six Tips That Will Make Your Guest Room Perfect

Being a house guest can be awkward. It is easy to feel uncomfortable if you have nowhere to retreat to. Thats why its really important to have a...

Ingenious Method to Get Rid of Ants at Your Home

Have you ever walked into the kitchen in the morning to go rinse off some dishes and spotted ants? Or maybe you have been showering and noticed...